The sluggish economic recovery and pressure to increase earnings continues to influence the leadership of banks and insurance companies to focus on driving down costs. The temptation, of course, is to offshore jobs – a strategy which promises a quick fix by reducing labour costs but one that also has serious ramifications.

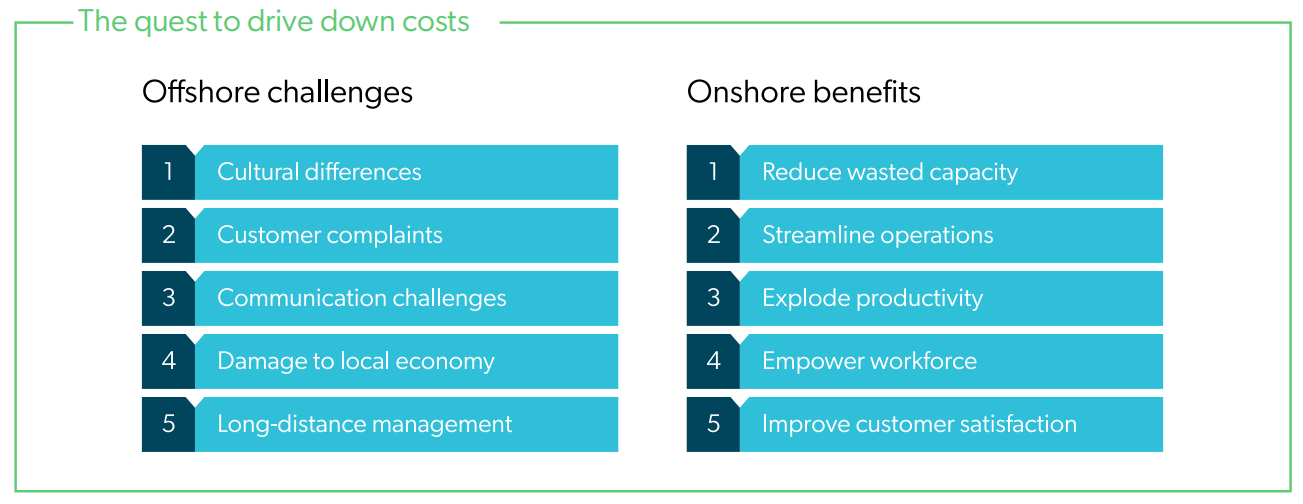

Cultural differences, customer complaints, damage to the local economy, and the complexity of long-distance management are just some of the problems organisations encounter when offshoring.

A plethora of recent press and research estimates that almost half of all offshoring projects fail outright or fail to meet expectations, raising the question of why any company would even consider offshoring when they have not yet exhausted their options at home.

By introducing a continuous improvement system, organisations can still drastically cut costs right here at home without unnecessarily damaging the local economy, employee morale and customer loyalty. Our clients regularly find that offshoring is no longer viable after a metrics-based, continuous improvement system has been applied to their onshore operations.

For example, one of our clients – a national insurance company with 16,000 employees – was looking to offshore a substantial part of their operations to benefit from labour cost arbitrage. They received initial price quotes from an overseas partner and made preparations to commence offshoring.

At the same time, however, they were introducing a continuous improvement system into other areas of the business, thereby routinely reducing costs in those areas by 30-40% over each implementation programme. To avoid unnecessarily transferring the existing inefficiencies to the overseas partner, they decided to clean up onshore operations before offshoring.

As part of the continuous improvement system, the company introduced new daily metrics for all staff, with a focus on behavioural change in the front-line management and their teams. They also introduced much richer planning and oversight metrics, as well as methods and tools for the management levels above the front line managers.

Through the embedding of a continuous Lean methodology focused on waste removal, operational efficiency improved radically and costs were reduced by 40%.

Still expecting to offshore, executives then approached the intended overseas partner again with the new productivity metrics. At the new cost, however, the offshore project was no longer viable because the overseas partner could no longer match the internal costs. All jobs remained at home.

THE PATH TO OPERATIONAL EXCELLENCE

A crucial first step on the road to operational excellence is to create visibility of what exactly is happening in a business’s daily operations. Such visibility can only be achieved with the introduction of a continuous improvement system that adopts a solid, metrics-based approach to daily management.

Creating visibility using operational metrics is the key to finding and eliminating inefficiencies.

Ensuring that the appropriate benchmarks are in place to underpin these metrics is equally important. Specifically, benchmarks should be calculated using ideal standards, rather than

average or historical processing times (which is the approach most organisations adopt).

By including waste and non-value-add activities in measurement metrics and standards, the inefficiencies and full potential of an organisation remain hidden.

Benchmarking processing times devoid of any non-value-add and waste activity is the foundation to systematically identifying and removing waste activities far into the future.

The only way to obtain correct benchmarks and fully understand what a team or business unit does is to watch it first-hand.

This entails conducting value-added assessments, which is the formal process of watching an activity from start to finish, while noting down the time taken to do that activity, any key steps within it, and any waste that occurs during that activity.

Value-added assessments help identify waste, establish reasonable standards, identify process improvements and enable the team leader to look at their workplace objectively.

Achieving operational excellence and a culture of continuous improvement also requires a management team that is actively managing. While this might sound obvious, most senior executives are not aware that their front-line management team actually spends very little time filling the role of leader and manager.

In fact, from the many thousands of studies our firm has conducted across large financial institutions and insurance companies around the world, the typical front-line manager only spends approximately 10% of their day actually managing their teams.

This is because they are too busy doing the work they should be managing, spending approximately 70% of the day on “doing the work”.