Executives overseeing transactional processing operations routinely question the leadership attributes held by front-line management within their organizations. Their concern is justified, as the typical front-line manager employs a highly reactive approach to management and focuses on “putting out res” rather than proactively managing their teams.

To be fair, this is partly due to the fact that most firms promote from within, then have no blueprint to continuously develop the internal craft of management.

It should thus come as no surprise to executives that the lower levels of their management structures are especially weak when it comes to leadership, even though they are very strong in terms of technical skills. What does surprise executives, however, is just how little time team managers spend filling the role of manager and leader.

A consistent theme emerges from hundreds of studies we have conducted in back-office processing areas. Frontline managers are acting as superior workers and spend negligible amounts of time engaging in crucial management functions – planning, organising, leading and controlling – to optimise team performance.

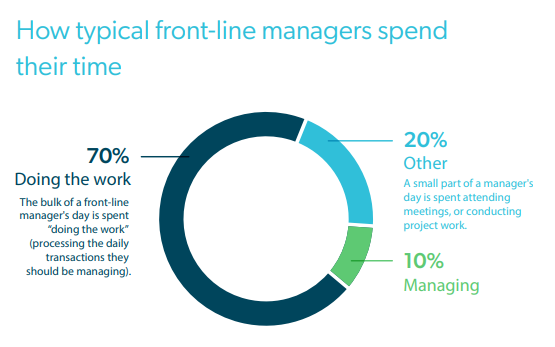

In fact, in most organisations, a typical frontline manager spends just 10% of their day on management activities, while devoting 70% to “doing the work” and 20% to meetings and projects.

While we have seen fluctuations in the time managers spend between “doing the work” and attending meetings, the portion of their day spent managing and optimising performance is consistently very low.

In contrast to what we see in transactional servicing, the manufacturing sector has witnessed much greater success in defining and adapting the role of the manager. This is partly due to manufacturing companies experiencing decades of intense global competition that has resulted in the evolution of management best practices.

Manufacturing companies have focused on how to best measure and manage their operations to produce high quality at a low cost. Their success in clearly differentiating between managerial and processing roles can also be attributed to the clearly visible difference between “line staff” and managers in the manufacturing setting.

For example, if a manufacturing manager joins his staff at the assembly line, it becomes immediately visible at all levels of the organisation that he is “doing the work”, rather than managing his team. Such visibility provides senior managers with the opportunity to intervene if the manager spends an excessive amount of time processing work rather than managing.

In back-office administrative environments, the practice of clearly defining the managerial role has not been equally embraced, much to the detriment of performance in this sector.

The distinction between “doing the work” and “managing the work” is grey, as the work is predominantly paper- or computer-based. The confusion about the role of a manager occurs despite the fact that most front-line managers have undergone leadership training at some point in their career.

Many have a college degree, have completed post-graduate study, or have participated in an internal development course. Managers will have been exposed to the work of some of the greatest management theorists of all times, including Taylor, Fayol, Webster, Drucker and Deming; all of whom have for decades advocated for the division of labor and the craft of management.

So, if front-line managers know that the basis of management is to maximise the output of personnel reporting to that role, then why do they spend so little time actively managing this effort? At Enlighten, we believe there are 3 key reasons why front-line managers in back-office environments don’t manage:

- Insufficient information.

- Lack of methodologies.

- Self-perpetuating behavioural norms (“This is not the way it’s done here”).

Insufficient Information

It is very difficult to manage something you do not measure, and most front-line managers simply lack access to a robust metrics system that provides them with information that matters. They have no way to measure efficiency, capacity, waste or the impact of errors. Without this information, managers are neither able to understand nor to effectively manage their team’s performance. They are also unable to conduct a range of essential management functions. For example, how can they use latent capacity if they do not know what capacity there is?